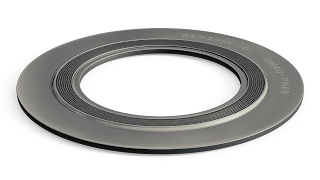

Spiral Wound Gaskets: An Introduction

Spiral Wound Gaskets are a type of gasket that is commonly used in high-pressure and high-temperature applications. They are made from alternating layers of metal and filler material wound together in a spiral pattern. The design of the gasket allows it to be very effective at sealing under extreme conditions. In this blog post, we will explore the features and benefits of Spiral Wound Gaskets. Features of Spiral Wound Gaskets Spiral Wound Gaskets have a number of features that make them an ideal choice for high-pressure and high-temperature applications. The following are some of the most important features of Spiral Wound Gaskets: Excellent sealing properties: The spiral wound design of the gasket allows it to conform to irregular surfaces and create a tight seal. This makes it effective in sealing fluids and gases under high pressure and temperature. High-temperature resistance: Spiral Wound Gaskets can withstand high temperatures without losing their sealing properties. The