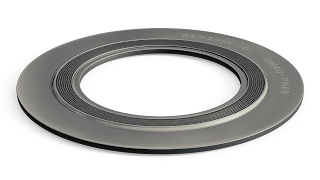

Spiral Wound Gaskets: An Introduction

Spiral Wound Gaskets are a type of gasket that is commonly used in high-pressure and high-temperature applications. They are made from alternating layers of metal and filler material wound together in a spiral pattern. The design of the gasket allows it to be very effective at sealing under extreme conditions. In this blog post, we will explore the features and benefits of Spiral Wound Gaskets.

Features of Spiral Wound Gaskets

Spiral Wound Gaskets have a

number of features that make them an ideal choice for high-pressure and

high-temperature applications. The following are some of the most important

features of Spiral Wound Gaskets:

Excellent sealing properties: The

spiral wound design of the gasket allows it to conform to irregular surfaces

and create a tight seal. This makes it effective in sealing fluids and gases

under high pressure and temperature.

High-temperature resistance:

Spiral Wound Gaskets can withstand high temperatures without losing their

sealing properties. They are commonly used in applications where temperatures

can reach up to 1000°F.

High-pressure resistance: Spiral

Wound Gaskets can also withstand high pressure, making them an ideal choice for

applications such as steam boilers, pipelines, and pressure vessels.

Corrosion resistance: Spiral

Wound Gaskets are made from a variety of metals and filler materials that are

resistant to corrosion. This makes them effective in applications where the

gasket may come into contact with corrosive fluids.

Benefits of Spiral Wound Gaskets

Spiral Wound Gaskets offer a

number of benefits over other types of gaskets. The following are some of the

most important benefits of Spiral Wound Gaskets:

Cost-effective: Spiral Wound

Gaskets are a cost-effective option for sealing high-pressure and high-temperature

applications. They have a longer lifespan than other types of gaskets, which

means they need to be replaced less frequently.

Versatile: Spiral Wound Gaskets

can be made from a variety of metals and filler materials, which makes them

versatile and suitable for a wide range of applications.

Easy to install: Spiral Wound

Gaskets are easy to install and require minimal preparation. They can be

installed quickly and easily, which helps to reduce downtime and increase

productivity.

Resistant to compression and

relaxation: Spiral Wound Gaskets are resistant to compression and relaxation,

which means they maintain their sealing properties over time. This makes them a

reliable option for long-term use.

Applications of Spiral Wound Gaskets

Spiral Wound Gaskets are used in

a variety of applications where high pressure and high temperature are present.

The following are some of the most common applications of Spiral Wound Gaskets:

Oil and gas industry: Spiral

Wound Gaskets are used in pipelines, refineries, and petrochemical plants to

seal high-pressure and high-temperature fluids.

Chemical industry: Spiral Wound

Gaskets are used in chemical processing plants to seal corrosive fluids and

gases.

Power generation: Spiral Wound

Gaskets are used in steam turbines, boilers, and other power generation

equipment to seal high-pressure steam and hot gases.

Food and the pharmaceutical

industry: Spiral Wound Gaskets are used in food and pharmaceutical processing

plants to seal high-temperature and high-pressure fluids.

Conclusion

Spiral Wound Gaskets are a

reliable and cost-effective option for sealing high-pressure and

high-temperature applications. They offer excellent sealing properties, high

temperature, and pressure resistance, and are resistant to corrosion. They are

versatile and can be used in a wide range of applications, from the oil and gas

industry to the food and pharmaceutical industry. If you are looking for a

reliable gasket solution for your high-pressure and high-temperature

applications. For more details visit the website.

Comments

Post a Comment